Processing Wastewater, Cleaner, Faster and Cheaper

Next Generation Gasification

A state-of-the-art hydro-thermal technology that turns high-moisture waste into renewable gas, clean water, and only safe byproducts.

Why We're Different

Supercritical Water Gasification recovers up to 90% of energy and valuable resources from high moisture waste, producing only renewable gas, clean water and safe mineral effluent.

The technology fully destroys hazardous & persistent organic pollutants, leaving no residual waste, while significantly reducing the CO₂ footprint of challenging waste streams.

Pure Cycle Power’s system processes feedstock in just 20–30 minutes, outperforming slower biological and thermal methods. The resulting gas is clean and dioxin-free, ready for direct injection into existing distribution networks.

Modular and decentralized system architecture enables seamless scalability, cost efficiency and location-agnostic plant deployment.

Once operational, SCWG systems run independently, powered by a fraction of self-produced renewable gas — with little to no need for external electricity.

Pure Cycle Power’s proprietary SCWG technology has been extensively validated through more than 20 years of research, development, and testing by a world-renowned scientific team.

Trusted by Leading Innovators in Sustainability

At Pure Cycle Power, we’re proud to collaborate with a growing network of partners—from pioneering research institutions to forward-thinking industrial leaders—who share our vision for a cleaner, circular future.

Revolutionizing Wastewater Treatment

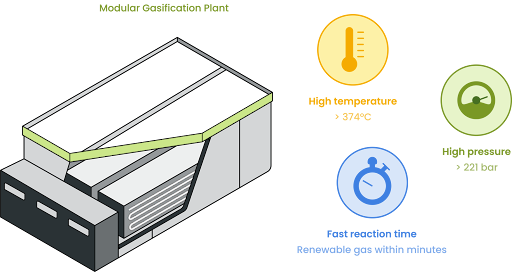

The Supercritical Water Gasification Process

Supercritical Water Gasification (SCWG) harnesses water in its supercritical state—achieved under extreme temperature and pressure—to decompose all organic matter at the molecular level. The process produces hydrogen-rich gas, sterilised water, and small amounts of solid mineral effluent, all with minimal odor and noise. The modular, lego-like system architecture enables flexible, decentralised deployment and high-throughput performance, even in compact setups.

Renewable Gas from

Wastewater

Our technology processes a broad spectrum of wastewater and sludge feedstocks, transforming even the most challenging waste streams into green energy and valuable materials, not only actively advancing circular economy principles, but also contributing to large-scale decarbonization.

Uses of Renewable

Gas

The produced gas can be integrated directly into existing infrastructure and gas distribution networks or converted into alternative fuels, enabling its use in heating buildings, supporting industrial processes, and improving the sustainability of transportation and mobility systems.

What’s in Our Gas

The produced gas contains a high concentration of hydrogen. As demand for hydrogen continues to grow, hydrogen generated through this process can also be utilized directly.

A fraction of the produced gas consists of carbon monoxide, which can be filtered out or used to produce additional synthetic fuels or chemical feedstocks.

Part of the produced gas consists of methane, a high-calorific-value energy carrier, widely used for power, heating, and transport. When sourced renewably, it helps cut fossil fuel use and emissions.

The extracted CO₂ is separated from the gas and is stored in liquid form, providing the flexibility to either repurpose it for industrial applications (CCU) or permanently store it (CCS).